MarisOmega specializes in natural fungal omega-6 ARA oil for infant and young child nutrition, a fatty acid that plays a crucial role in infant formula. We provide omega-6 ARA oil and powder for applications demanding a clean taste and high oxidative stability, such as infant formula and fortified health foods. Our products boast a high ingredient load, ensuring extended shelf stability, and we offer assistance with shelf-life testing for our customers.

MarisOmega’s manufacturing partnerships make it easy to develop new products. With a wide range of formulas, different ingredient loads and shell matrix formulations, we can provide exactly the omega-6 ARA oil or powder you need. Where needed and commercially feasible, customized variations can be developed and tested at pilot scale, efficiently and fast. Our range includes protein-based formulas as well as starch-based products for hypoallergenic and acidic foods. Applications for our omega-6 ARA oils and powders include infant formula, dietary supplements and functional foods.

Our omega-6 ARA oils and powders are derived from natural strains of single-cell ARA fungi (Mortierella alpina). Compliant with European Union regulations on single-cell oils as novel foods, we adhere to all regional requirements, encompassing conditions of use, specific demands for infant nutrition, and organic product standards. Our collaboration extends to cutting-edge facilities that meet both local and international standards, including good manufacturing practices and food hygiene.

Every product undergoes meticulous third-party testing, in addition to assessments conducted throughout the production process. Our approach to sourcing and qualifying omega-6 ingredients goes beyond mere specification compliance. This involves:

We offer various types of premium-quality omega-6 ARA oil and powder, all of which must meet the strict quality criteria we set. As an example, see below the supply-chain set-up and quality criteria for our omega-6 ARA oil: MarisARA Powder.

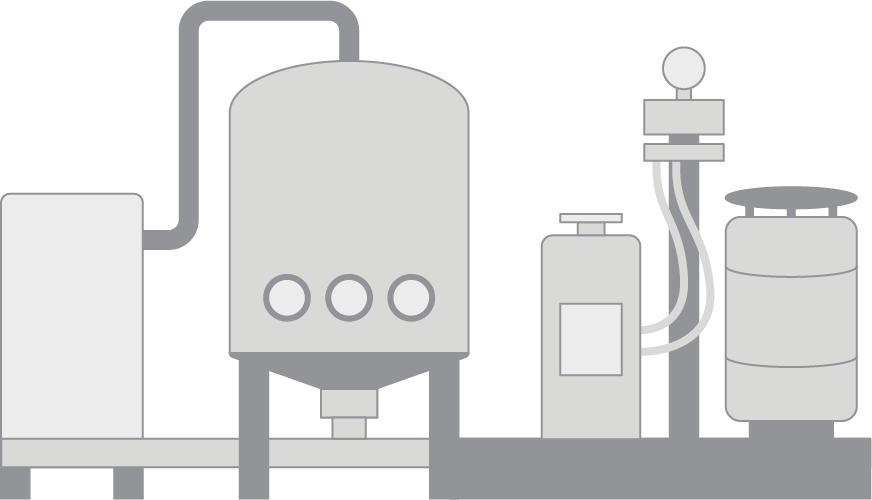

All ingredients are tested to comply with internal standards, including a lack of genetic modification and regulatory compliance for all relevant applications and markets.

All water-soluble ingredients are dissolved and blended under vacuum condition to avoid undesireable oxygen entry. DHA oil is added by an in-line emulsification process, keeping temperatures low for the best protection from oxidative impairment.

The homogenization and pasteurization processes have been optimized for limited duration and low temperature, which also applies to minimum standing times in holding tanks.

Packaging is carried out in a fully closed, fully automated area, utilizing robots and automated guided vehicles, providing the highest safety and precision. The product is then filled in bags of various sizes, combining vacuum and inert gases to avoid any oxygen contact.

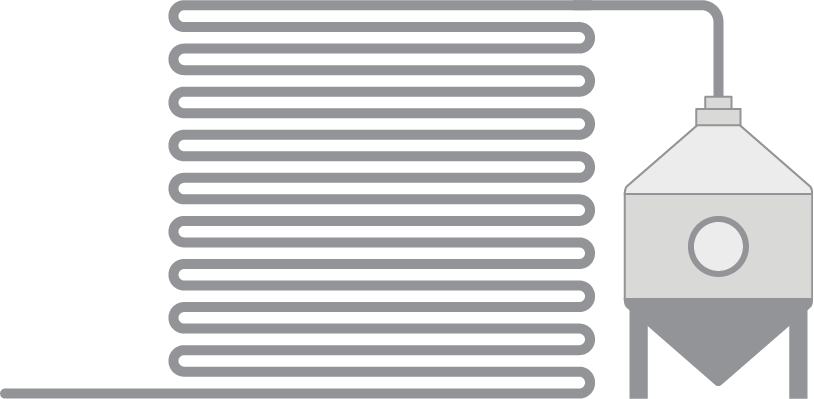

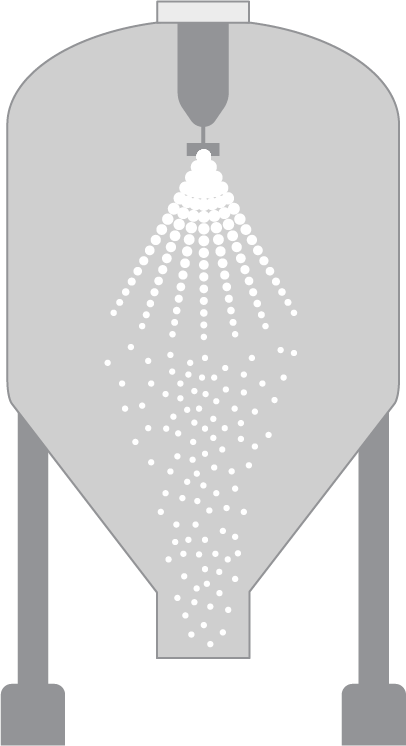

The spray-drying process is carried out at temperatures considerably below industry standard. Besides limiting oxidation, this low temperature is also beneficial for the microcapsules’ shell integrity. At higher temperatures, more rapid water migration from the shell may impair its stability.

Hendrik Rösel

Lead IMF Sales

Edda Marwede

Product Manager

Chris Kommerowski

Sales Director

Marco Heins

Product Manager

Kruna Ramljak

Product Manager

Christina Wegener

Logistics & Sales Manager

Felix Wohlers

Logistics Manager

Dirk De Deyn

Sales Director

Charlotte Grüttner

Logistics Manager

Tim Rathje

Product Manager

Hendrik Rösel

Sales Manager

Edda Marwede

Sales Manager

Ina von Oertzen

Business Development Director

Loyana Camelo

Assistant Sales & Logistics

Ina von Oertzen Sales Director

Hendrik Rösel Lead IMF Sales

Edda Marwede Product Manager

Tim Rathje Product Manager

Loyana Camelo Logistics Manager

Chris Kommerowski Sales Director

Marco Heins Product Manager

Kruna Ramljak Product Manager

Christina Wegener Logistics and Sales Manager

Felix Wohlers Logistics Manager

Dirk De Deyn Sales Director

Ina von Oertzen Business Development Director

Tim Rathje Product Manager

Hendrik Rösel Sales Manager

Edda Marwede Sales Manager

Charlotte Grüttner Logistics Manager

Loyana Camelo Assistant Sales & Logistics